The KAYAN team has successfully designed constructed and employed a wide variety of remedial technologies worldwide.Technologies are site-specific custom designs per the client's need.

The KAYAN team has constructed equipment for several complex remediation and recycling projects throughout the world.

KAYAN management garnered valuable experience and expertise working emergency responce and superfund sites throughout the United States. The team then moved on to international environmental projects.They successfully completed projects in 29 countries and due to the unique nature of each project have gained irreplaceable industry knowledge.

Read More

TTI with its partners is designing a secondary manufacturing facility for a large waste management facility in Vietnam. The facility will be located in the Northern Province and specialize in refinery waste.

KAYAN has been awarded a contract to utilize mechanical separation combined with indirect thermal remediation to assist Global Environmental Management with their current waste management operations.

KAYAN & Vivakor’s patent pending, closed looped hydrocarbon extraction technology was invented to solve a pivotal problem within the state of Utah: how to monetize over 30 billion barrels.

The innovative design of the Infrared units allows for high temperature treatment of soil without the use of moving parts. It utilizes vapor pressure created by the infrared heat to drive contaminants from the soil. This takes some ...

Read More

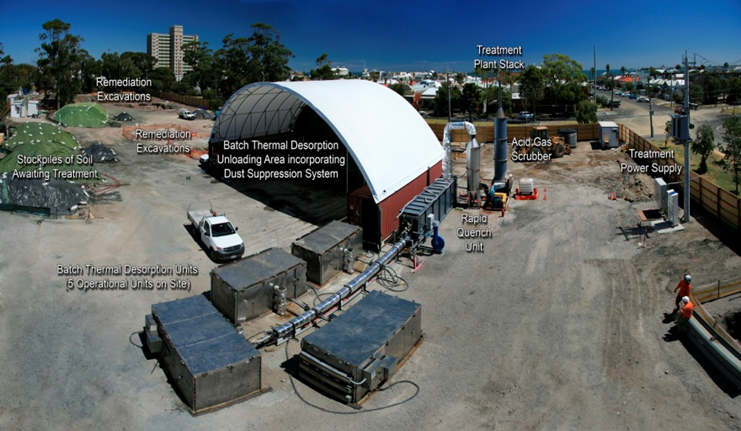

Indirect thermal desorption is a proven treatment technology that effectively remove voilate organic compounds(VOC's) from soil and several other contaminated waste streams from soil and sludge.THermal desorption occurs...

Read More

Direct Fired Thermal Desorption (DFTD) consists of a counter flow desorber drum and attendant air pollution control equipment. The rotary drum desorber operates the flow of soil counter to the flow of combustion gases and ..

Read More

Lower cost and less labor intensive compared with other methods

Higher production results per well

Long Lasting effects

Higher revenues

Flexibility,mobilty,offshore and onshore capabilities,fine tuning of technologies

In most cases no need for chemicals

Possible to stimulate at sub molecular level

Easy to combine with other methods

Long lasting effects(3 months to 2 years)

Only a short down time for the wells(0-3 hours)